- +1 213 498-6298

- yangcecilia26@gmail.com

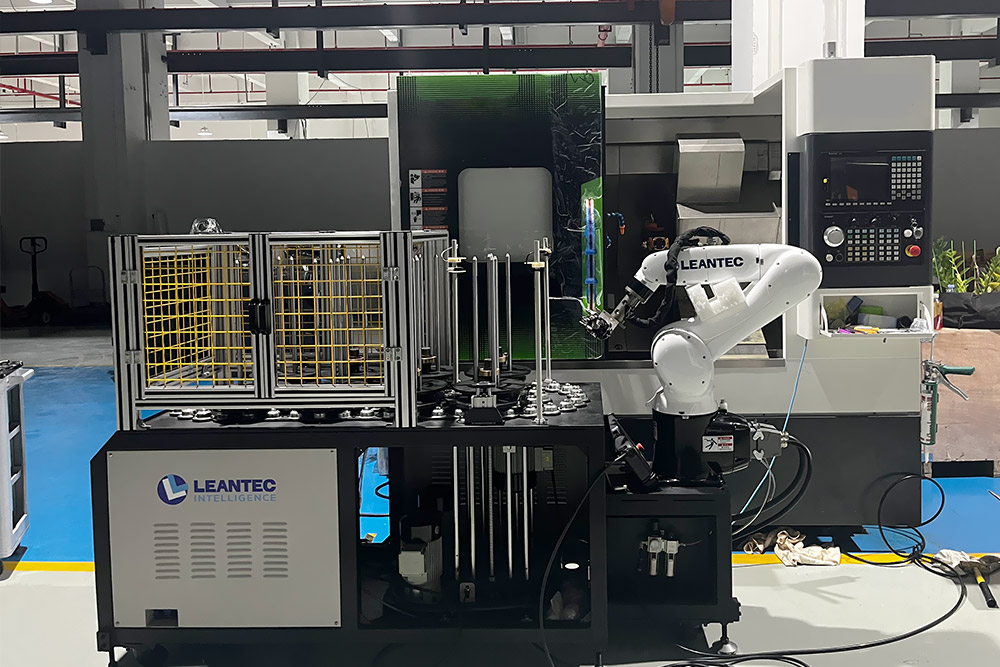

PROWAY CNC currently offers a diverse range of products, including the high-performance HMS series and the cost-effective QPR series, covering automated CNC lathes with robotic integration, high-precision turn-mill centers, and multi-axis compound machining models.

Since establishment, PROWAY Precision has been dedicated to the research, development, and manufacturing of intelligent CNC lathes, with a strong focus on serving industrial automation needs. Guided by the principle of customer-centered innovation, the company pays close attention to every detail in CNC lathe design and production. With years of deep industry experience and a highly skilled technical team, Chengtai Precision provides comprehensive pre-sales, in-sales, and after-sales service to ensure customer satisfaction and long-term reliability. The company currently offers a diverse range of products, including the high-performance HMS series and the cost-effective QPR series, covering automated CNC lathes with robotic integration, high-precision turn-mill centers, and multi-axis compound machining models. Its machines are widely used across multiple industries, including new energy vehicles, military manufacturing, 3C electronics, 5G communications, medical devices, aerospace, and heavy machinery engineering.

Real-World Solutions in Action

PROWAY CNC currently offers a diverse range of products, including the high-performance HMS series and the cost-effective QPR series, covering automated CNC lathes with robotic integration, high-precision turn-mill centers, and multi-axis compound machining models.

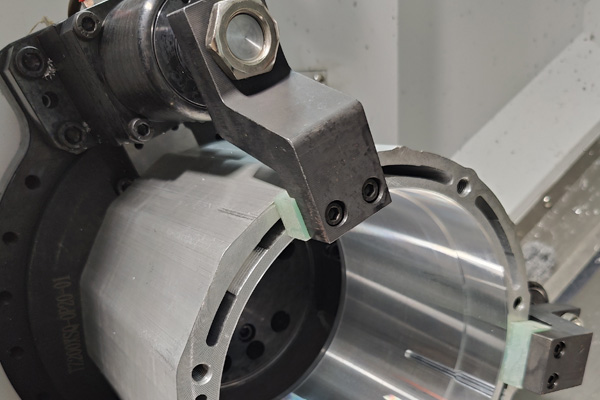

The machine is built with high-strength HT300 cast iron, formed in one piece and subjected to multiple stress-relief treatments for superior rigidity, vibration resistance, and long-term stability. It features THK or equivalent international-grade linear or box guideways, processed by high-frequency quenching and precision grinding for exceptional wear and pressure resistance. The precision slider with preloaded design ensures a repeat positioning accuracy of ±0.003mm. The HTK C3-grade ball screw with pre-tensioned structure, combined with a high-precision direct-drive coupling, delivers fast response and minimal transmission error. The main spindle, supplied by JEN CHUAN (Taiwan) or equivalent brands, undergoes dynamic balancing with runout less than 0.003mm, paired with high-grade bearings and a temperature-controlled lubrication system for long-term precision. Every unit is inspected using laser interferometer, ballbar, and CMM testing, and assembled by experienced technicians. Equipped with FANUC / Siemens / SYNTEC systems, it supports full closed-loop control, ensuring smooth tool paths and outstanding machining performance.

We have always adhered to the philosophy of “technology-driven development and quality as the foundation.” From structural design and electrical control to assembly and commissioning, every process is strictly supervised。

From machine structure, spindle configuration, and automation integration to control systems and exterior design, every detail can be tailored to your specific production requirements. Offering turn-key solutions.

Our machines are widely used across multiple industries, including new energy vehicles, military manufacturing, 3C electronics, 5G communications, medical devices, aerospace, and heavy machinery engineering.

The company has a professional service team, capable of providing customers with timely and professional technical support and solutions, ensuring customer satisfaction during product usage.

With a production area of over 5,000 square meters, the facility features CNC machining, precision assembly, electrical testing, and quality inspection zones, all organized with efficient and systematic layout to ensure streamlined operations.

No posts found!

Interested in our industrial intelligent CNC lathes? Let us provide you with a tailored quote based on your specific needs.